EPOWER300

COMPACT, VERSATILE AND EASE TO USE

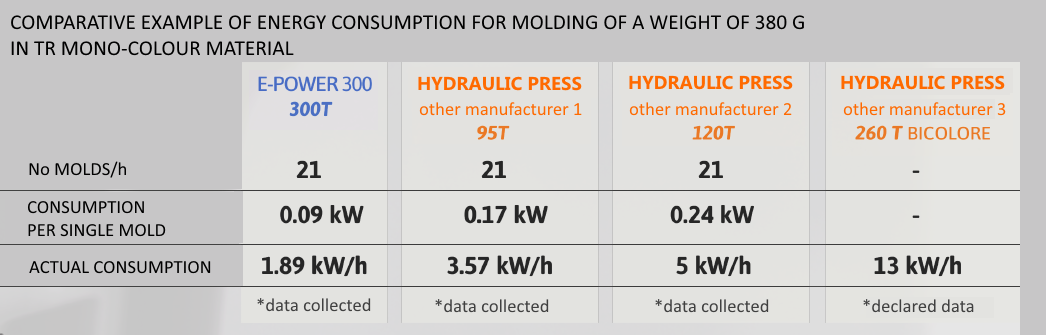

E-POWER 300 guarantees better performance than traditional hydraulic presses with a significant reduction in consumption and environmental impact.

VERSATILITY

THE MOLDING OF DIFFERENT TYPES OF MATERIAL WITH THE SAME SET UP IS NOW POSSIBLE WITH E-POWER 300

An injection system with servo-extruder specifically designed for the molding of various types of thermoplastic materials (PVC, TPU, TR, EVA, RETICULAR EVA), thermosetting and vulcanised elastomers (RUBBER) used in the molding of the bottoms for single-tone, two-tone and three-tone footwear. Given its particular versatility, E-POWER 300 is also very effective in other productive sectors (automotive and general components) where precision, repeatability and low operating costs are required for high quality products.

MODULARITY

E-POWER 300 WAS DESIGNED TO EXPLOIT THE ADVANTAGES OF A MODULAR SYSTEM TO THE MAXIMUM

An extremely compact structure that does not require side accesses and can therefore be placed side by side in contact with other E-POWER 300 presses with a significant reduction in the spaces occupied for the same production capacity.

PRECISION

PRECISION-FOCUSED DRIVE TECHNOLOGY

The use of servomotors in all machine drives, including the servo-extruder, results in a high degree of repeatability of molding which significantly impacts both on the quality of molding and on the reduction of waste.

INNOVATION

AUTOMATIC DETERMINATION OF OPTIMAL PROCESS PARAMETERS FROM THE FIRST MOLDED ITEM

With the E-POWER 300 design, important calculation algorithms have been developed that are able to automatically identify the quantity of material to be injected into the mold cavity. Thanks to this feature, it is not necessary to change the molding parameters when changing the size.

To see the video of machine at work

For further information and to get the product technical data